Components of Helmets and their roles?

In the following article, we will be discussing the topic components of helmets and their roles. A safety helmet is one of the most important or significant items of personal protective equipment used by motorcycle riders mainly to protect the head against impacts. Helmets won’t prevent accidents, but they clearly will cut down on injuries and deaths when collisions or accidents occur.

Generally, a helmet has the following components which are stated below with their roles:

The Shell:

The shell of a helmet is a pressure moulded thermos set or an injection moulded thermoplastic, which is made of fibre glass or reinforced with glass fibres.

It absorbs energy in the impact: and thus the underlying foam deforms. At moderate speeds, the shell can take 1/3rd of the impact energy.

It distributes local forces from an impact or collision: rigid or stiff objects like a projecting beam or a stone can cause a skull fracture at low forces, the shell acts to distribute the force of such impact eliminating or removing the risk of penetration.

It also allows sliding on road surfaces: the shell having a convex shape and being rigid allows the helmet to slide along a road surface without there being an excessive force.

And it protects the face and temples: a full-face helmet is beneficial or advantageous in protecting the face and jaw. The chin bar of such helmets contain rigid foam to absorb energy for direct blows or impacts on the chin, hence prevent facial bone fractures and prevent the lower part of the forehead and temple being struck.

The Protective Padding:

Protective Padding is a moulding of polyurethane foam or polystyrene beads. It provides or offers a stopping distance for the head. The foam can compress by around 90% during an impact, however, it recovers partially afterwards. But this helps to increase the stopping distance hence reducing the peak deceleration of the head. It also protects the head as much as possible. Furthermore, there is a layer of comfort padding to provide or offer comfort to the wearer.

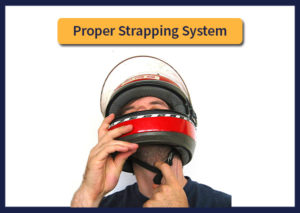

Proper Strapping System:

It is essential or necessary to wear a well-fitting helmet for the effective or successful working of chinstrap system. To test if the helmet fits properly on your head, tightly fasten the chinstrap and then pull the helmet off forward by gripping or holding the rear and then pulling. The strap must be threaded correctly in order for the buckle to lock the strap when it is pulled from the chin side. The strap must be pulled as tight as is bearable or endurable under the chin.

In conclusion, you can say that the conventional motorcycle helmet has two principal protective components: a hard, thin, outer shell usually made from fibreglass, Polycarbonate plastic, or Kevlar and a thick, soft, inner liner usually made of expanded polypropylene or polystyrene “EPS” foam. The purpose or motive of the hard outer shell is:

To prevent penetration or piercing of the helmet by a pointed object that might otherwise puncture the skull, and

To provide or offer structure to the inner liner so it does not disintegrate upon abrasive or harsh contact with the pavement. This is important or significant because the foams used have very little resistance to abrasion and penetration.

The purpose of the foam liner is to crush or compress during an impact, thereby increasing the distance and period of time over which the head stops and reducing its deceleration.